Bayesian Deep Learning for Manufacturing (dlmfg): Documentation¶

Framework¶

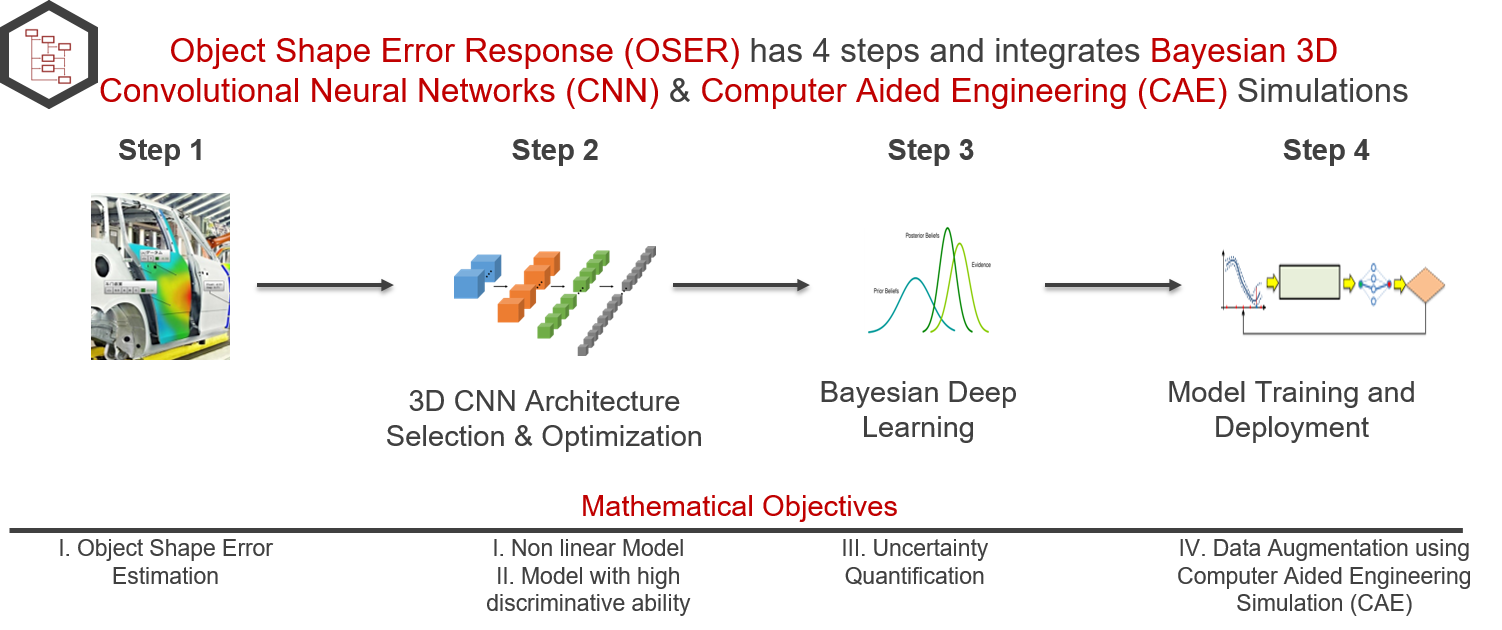

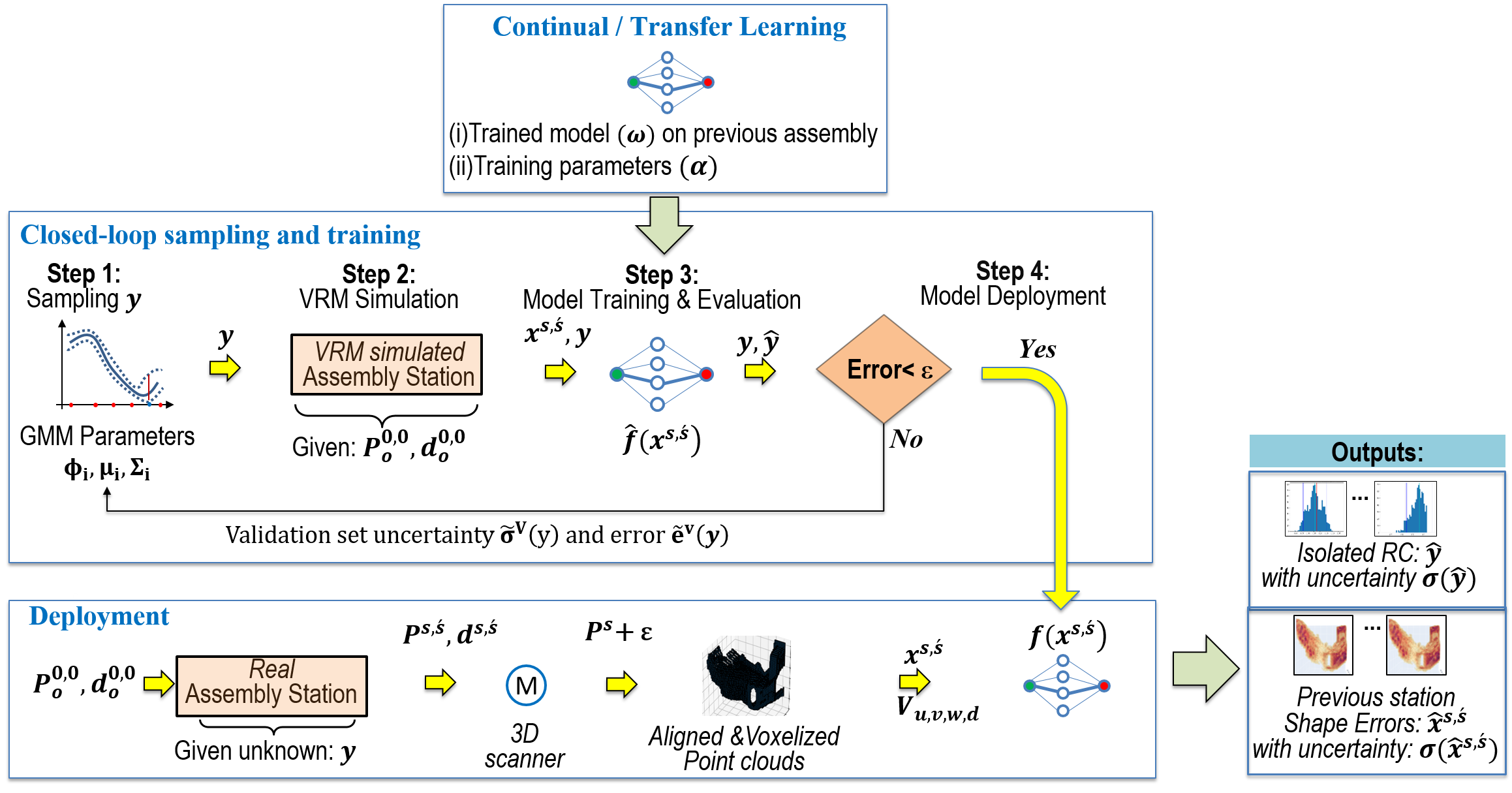

The research aims to develop artificial intelligence based solutions by integrating multi-fidelity Computer Aided Engineering (CAE), Bayesian Deep Learning and 3D point cloud data from optical scanners to enable process design, process monitoring, automated root cause analysis, automated correction in various phases of the manufacturing production cycle with the final aim of achieving Closed Loop In-Process Quality Control for Multi-Stage Manufacturing Systems. In doing so it proposes a new research niche Object Shape Error Response (OSER) that is aimed at solving root cause analysis (RCA) problems in the field of manufacturing. Inherently diagnosis of manufacturing processes such as assembly, stamping, additive manufacturing and machining translates into estimating the object error patterns in the final product and relating these patterns to abnormal variations in the process parameters. The library builds on the work done in 3D object detection done using 3D Convolution Neural Networks, 3D U-Nets to relate point cloud data to process parameter variations. The work is done keeping in mind the transferability and scalability to various manufacturing systems. The figure below represents the overall framework of the research in combining CAE simulation, deep learning and closed-loop sampling.

Fig 1: Overall Research Framework¶

The details for the application area, the challenges faced and the solutions provided by the library are summarized in the documents linked below

Bayesian Deep Learning for Manufacturing: A Research Perspective

Bayesian Deep Learning for Manufacturing: A Software Perspective

Contents¶

- Installation and Implementation

- Real System Implementation (3D Optical Scanner: WLS400A)

- Library Configuration

- Data Description & Processing

- Model Architecture

- Deep Reinforcement Learning for Control and Correction

- Model Architecture Selection

- Bayesian Deep Learning

- 3D U-Net Architecture Global Interpretability

- 3D U-Net Architecture Local Interpretability

- 3D U-Net Segmentation

- Class Structure: Objects and Methods

- Key Measurement Characteristics (KMCs)

- Utilities

- Continual and Transfer Learning

- Active Learning/Adaptive Sampling

- Visualization

- Case Study: Positioning and Clamping Variations for Halo

- Case Study: Door Inner and Hinge Reinforcement Multi-Stage Assembly

- Case Study: Cross Member Multi-Station Assembly

- Research and References